Our vision

Establish a more efficient industrial base, so that everyone has more abundant material resources, expanding human footsteps.

ALLTI Metal

ALLTI Metal CO.,LTD, Located in China's famous Baoji-Xi'an titanium industrial chain areas, is committed to producing semi-finished titanium and its alloy with ISO9001: 2008 international quality management system certification.

ISO9001: 2008 international quality management system certification. We supply most basic forms such as wire, sheet, plate, bar, tube, pipe, disc, ring, fasterner and more. Our products are mainly according to ASTM, AMS, AWS, ASME, ISO, DIN, JIS international standard. We have experience in most major market segments including aviation, aerospace, medical treatment, electroplating, petrochemical, oil & gas, mining, military and others.

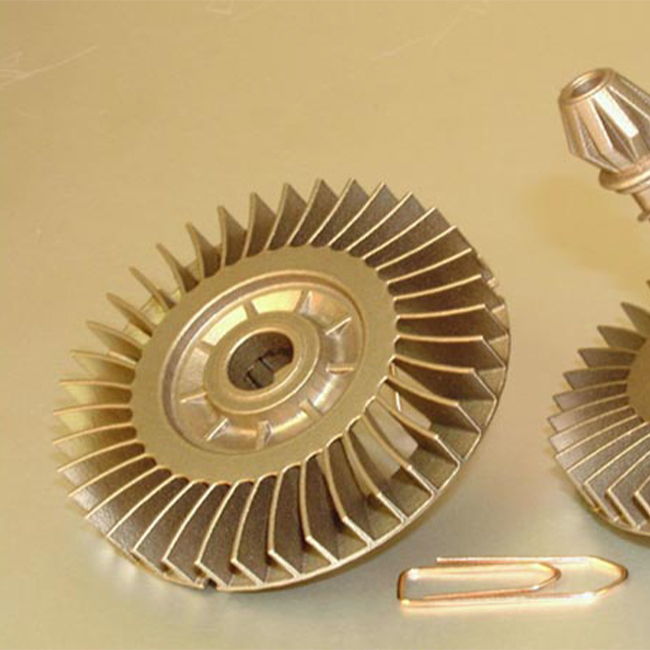

Our R & D team invested spherical titanium powder since the beginning of 2013. We apply the plasma heat source and heat sensing composite design, end-to-end vacuum design without argon, advanced technology brings higher rate of final products, it lead to lower cost titanium powder.

We have a common standard product inventory, such as titanium wire, bar and sheet. Others are semi-finished billets and slabs, to make sure your shorter delivery time. Whatever your needs are small or large. We look forward to becoming a reliable partner for your organization.

What we can do?

- Titanium powder (Spherical & HDH)

- Titanium wire (Ordinary & low oxygen)

- Titanium bar (Ordinary & low oxygen)

- Titanium sheet and plate

- Titanium tube and pipe

- Titanium fastener

- Titanium ring

- Titanium disc

Where need titanium?

- Aviation and aerospace

- Motor sports

- Defence technology

- Medical technology

- Offshore / Petrochemical

- Chemical and process engineering

- Plant and equipment manufacturing

- Electroplating

- Turbine manufacturing

Why choose us?

- Best Quality & Fast delivery

- Unparalleled service

- No minimum order

- Technical support

- Reach us at any time

- Documentation accuracy

- Provide your order’s status termly

- Material traceability